1. Hospitality Industry. 2. Beauty Salons and Spas. 3. Healthcare Facilities....

1. Automated Production Process. 2. Customizable Towel Sizes and Folding Patterns. 3. High-Speed Production and Energy Efficiency....

Introduction. Market Trends. Opportunities and Challenges. Conclusion....

1. Regular Cleaning and Sanitization. 2. Routine Maintenance Checks. 3. Proper Storage and Handling....

Introduction. Step 1: Set Up the Machine. Step 2: Load the Towel Material. Step 3: Start the Production. Conclusion....

HBJX-200ss -R2.5 is a device designed to provide mini magic compressed towels. Finished product size specification :SCircle:Phi25mm, Thickness: Confirmed according to weight and specifi...

This machine is a multi-functional equipment for processing and production. It can complete drilling, slitting and rewinding at one time.Specification model: HBJX-W1600-DD type Applicab...

HBJX-200ss-S2840 is provide portable mini compressed towels equipment. Square: 28*40mm, Thickness: Confirmed according to weight and specification. Expand reference standard size: 240*3...

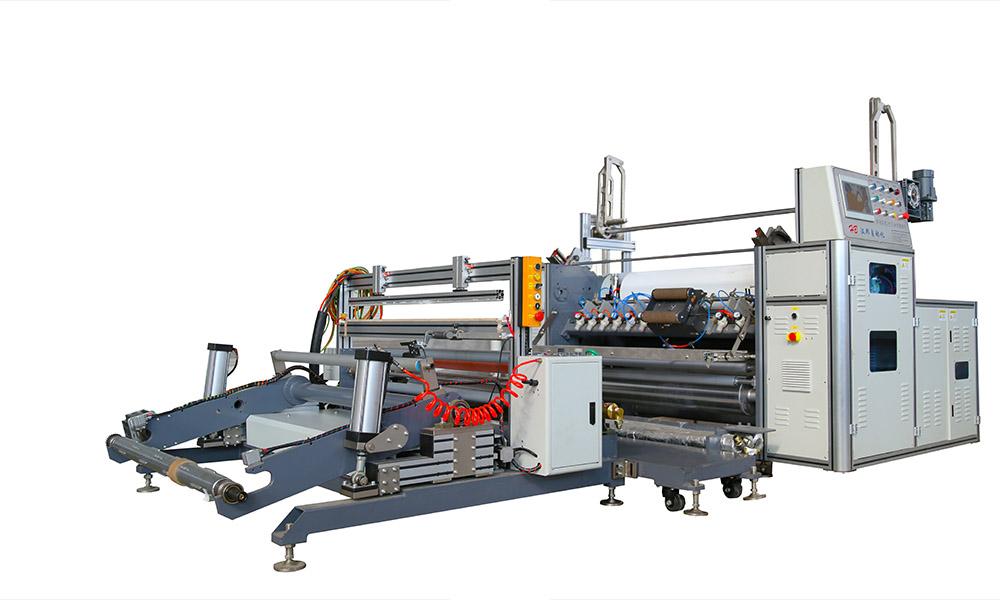

The non-woven double layer 3D lamination embossing machine is a cutting-edge technology that has revolutionized the compressed towel industry. With its advanced capabilities, this mach...

The compressed bath towel machine is an advanced technology that revolutionizes the bath towel industry. This machine utilizes innovative techniques to compress and package bath towels...

Introduction: This case highlights the successfulimplementation of a Non Woven Single Unwinding Double Rewinding EmbossedPunching Slitting Machine for a prominent baby diaper manufac...

This case study focuses on a Vietnamesecustomer who operates in the compressed towel industry. They were seeking to enhance their productionprocess by incorporating a Non-Woven Fabric...