HB is a manufacturer of Compressed Bath Towel Machine,with design, manufacture, and trading as one.It used in the hygiene and personal care industry, providing...

The Automatic Compressed Bath Towel Machine has simplified our towel inventory and replenishment process. It's a time-saver for our staff....

1. "The Automatic Compressed Bath Towel Machine is a game-changer for our hotel. It saves space, reduces laundry volume, and ensures every guest gets a fresh to...

The fully automatic compressed bath towel machine adopts automatic compression technology, which has a more perfect compression effect and can help you save mor...

1. Efficient Production Process. 2. Compact and Convenient Packaging. 3. Versatile Applications....

I. Travel and Outdoor Activities. II. Hospitality and Tourism Industry. III. Healthcare Facilities....

Convenience in Travel and Outdoor Activities. Hygiene and Safety in Public Facilities. Cost Savings and Efficiency for Businesses....

Enhancing Manufacturing Efficiency. Convenience for Customers. Sustainable and Eco-Friendly Solution....

Introduction. Advanced Nonwoven Fabric Technology. Key Components and Functionalities. Conclusion....

Introduction. Smart Automation. High-Speed Production. Quality Control and Customization. Conclusion....

1. Advanced Automation. 2. Customization and Flexibility. 3. Eco-Friendly Operation....

The compressed bath towel machine is an advanced technology that revolutionizes the bath towel industry. This machine utilizes innovative techniques to compres...

Introduction. Enhanced Efficiency and Convenience. Enhanced Hygiene and Sustainability. Market Impact and Future Prospects. Conclusion....

1. Automated Operation. 2. High Efficiency and Productivity. 3. Customizable Towel Compression....

Step 1: Preparing the Raw Materials. Step 2: Setting Up the Machine Parameters. Step 3: Operating the Machine....

Step 1: Prepare the Machine. Step 2: Load the Compressed Towel Capsule. Step 3: Activate the Machine....

Step 1: Preparing the Machine. Step 2: Loading the Raw Materials. Step 3: Operating the Machine. Conclusion....

Introduction. Market Size and Growth Prospects. Competitive Landscape and Key Players. Conclusion....

Introduction. Market Demand. Market Trends and Opportunities. Conclusion....

The client, a prominent distributor of textile products in Bangladesh, aimed to enhance their manufacturing capabilities and introduce cost-effective solutions...

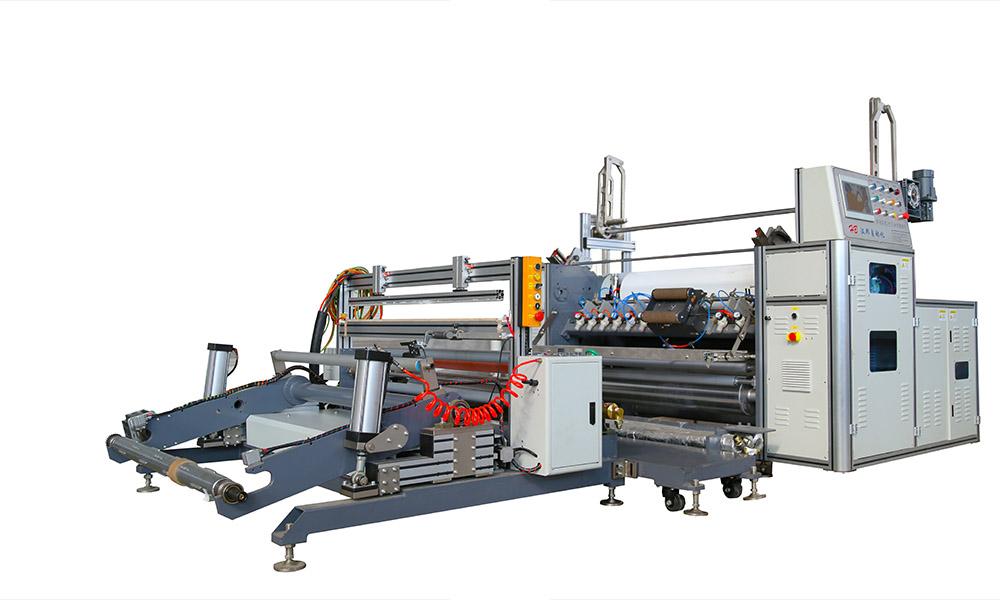

2 machines, operated by one person, with a production width of 190mm, 60 meters per minute, and an actual output of 1.2-1.3 tons/machine in 12 hours....

Applications:Processes such as embossing, punching, and laminating non-woven materials are often used in the production of diapers and sanitary napkins....

HBJX-300ss -R4.5 is a provide Expandable Disposable compressed towels. Finished round compressed towel machine, molding size: diameter 4.5mm: the smallest size that can be produced is 2...

The compressed bath towel machine is an advanced technology that revolutionizes the bath towel industry. This machine utilizes innovative techniques to compress and package bath towels...

Compressed towel machines have revolutionized the towel industry by providing a more convenient and space-saving solution for various settings. This article explores the applications o...

In recent years, the demand for diaperproducts has been rapidly increasing in the Philippines. As a result, many local manufacturers arelooking for innovative solutions to streamline ...

Introduction: This case highlights the successfulimplementation of a Non Woven Single Unwinding Double Rewinding EmbossedPunching Slitting Machine for a prominent baby diaper manufac...