In recent years, the demand for diaper products has been rapidly increasing in the Philippines.

As a result, many local manufacturers are looking for innovative solutions to streamline their production processes and improve efficiency.

This case focuses on implementation of Diaper core folding machine for a leading diaper manufacturer in the Philippines.

Client Background:

Our client, ABC Diapers, is one of the top diaper core manufacturers in the Philippines.

With a strong commitment to quality and customer satisfaction, ABC Diapers aims to provide affordable and reliable diaper products to meet the needs of parents across the country.

However, with the rising demand, they faced challenges in meeting production targets while maintaining product quality consistently.

Problem Statement:

ABC Diapers required a solution to increase their production capacity and eliminate manual folding processes.

The existing manual folding method was time-consuming, labor-intensive, and prone to human errors, resulting in decreased productivity and compromised product consistency.

Solution:

After thorough research and consultation, the client decided to invest in a state-of-the-art diaper core folding machine.

The machine offered automated folding capabilities, allowing for faster production cycles and improved product quality control.

It could fold diapers in precise dimensions, ensuring uniformity across all products.

Features and Benefits:

1. High Speed and Efficiency:

The diaper core folding machine boasted advanced technology that enabled high-speed folding, significantly reducing production time and increasing output.

With its efficient design, it eliminated the need for manual folding, freeing up workers for other important tasks.

2. Customization Options:

The machine offered various settings and customization options, allowing ABC Diapers core to produce different sizes and styles of diapers according to market demand. This flexibility contributed to meeting evolving customer preferences efficiently.

3. Quality Control:

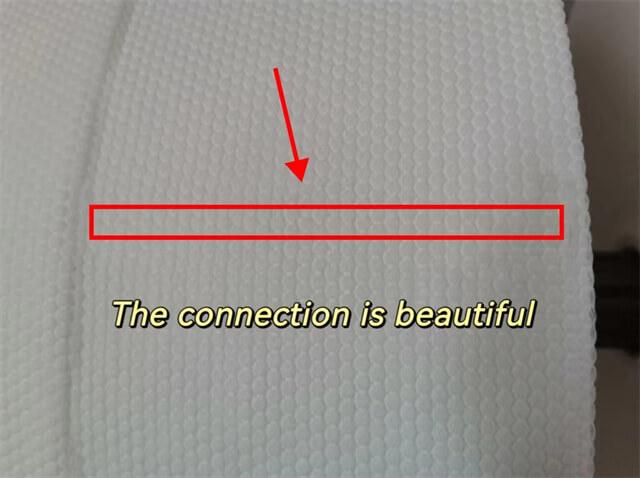

The automated folding process ensured consistent and accurate folding, minimizing defective products.

This improved overall product quality, contributing to enhanced customer satisfaction and brand reputation.

4. Cost Savings:

By replacing manual folding with an automated process, ABC Diapers experienced a reduction in labor costs.

Additionally, the machine's energy-efficient design contributed to savings in electricity consumption.

Implementation and Results:

Once the diaper core folding machine was delivered and installed, ABC Diapers provided thorough training to their production team on operating and maintaining the machine.

The transition from manual folding to automated folding was seamless, and the initial results were promising.

The machine effectively increased production capacity by 40%, allowing ABC Diapers to meet market demand more efficiently.

Moreover, the reduction in labor costs and improved product quality resulted in significant cost savings for the company.

Conclusion:

The successful implementation of the diaper core folding machine at ABC Diapers demonstrates the significant benefits of automation in the manufacturing industry.

By investing in cutting-edge technology, the company streamlined their production process, increased output, reduced labor costs, and improved product quality. This case serves as a testament to the positive impact that automation can have on businesses in the Philippines and beyond, as they strive for efficiency and competitiveness in the global market.

Nonwoven Machines Market Leader!