This case focuses on a Vietnamese customer engaged in the processing and production of sanitary napkins.

They sought to enhance their production processes by incorporating nonwoven embossing machines into their operations.

This machine will enable them to create unique and visually appealing patterns on non-woven fabrics, ultimately increasing their competitiveness in the market.

background:

Vietnamese customers are established players in the sanitary napkin industry and recognize the growing demand for high-quality products that combine functionality and aesthetics.

They realized the importance of staying ahead of the competition and decided to invest in advanced machinery to meet these ever-changing customer needs.

challenge:

Customers face several challenges in achieving the required product quality.

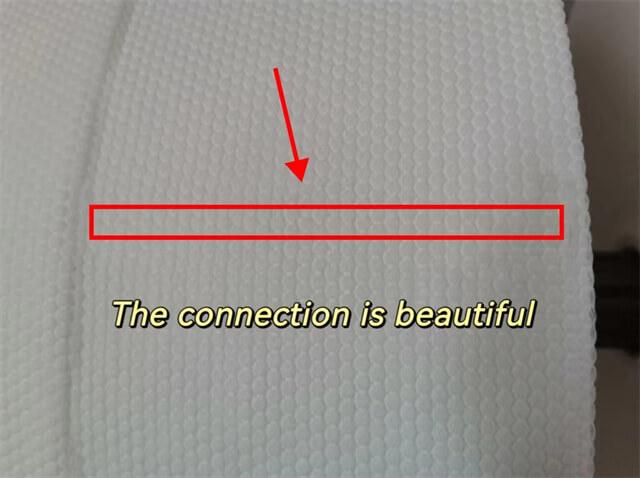

First, they needed to efficiently produce nonwovens with embossed patterns without compromising the integrity of the fabric. Second, they aimed to achieve consistent embossing effects on various types of air-through nonwovens.

Finally, they found a reliable machine supplier who could provide training, technical support and efficient after-sales service.

solution:

After extensive research and evaluation, the customer selected our company as its supplier of non-woven embossing machines.

Our machines stand out for their advanced features such as precise temperature control, adjustable pressure settings and user-friendly interface.

These features allow for customization, ensuring complex and consistent embossing patterns across different fabric types.

implement:

Our team works closely with customers to install and set up embossing machines in their production facilities.

As part of the implementation process, we provided comprehensive training to their staff to ensure they were skilled, efficient and safe in operating the machines.

We also conducted trial runs to evaluate and refine the embossing parameters according to their specific requirements.

result:

Vietnamese customers have achieved remarkable results by integrating our nonwoven embossing machines into their production processes.

They are able to produce high-quality sanitary napkins with visually appealing patterns that meet and exceed market expectations.

The efficiency of the embossing machine has significantly increased their productivity, allowing them to meet the growing demands of domestic and foreign customers.

in conclusion:

This Vietnamese customer successfully integrated our nonwoven embossing machine, proving its value in the sanitary napkin industry.

By investing in advanced machinery and working with reliable suppliers, they are able to improve product quality, increase productivity and gain a competitive advantage in the market.

This case study provides an example for other companies in the industry seeking to improve their manufacturing capabilities and meet changing customer needs.

Nonwoven Machines Market Leader!