introduce:

In this context, we will explore the successful implementation of a scalable disposable compressed facial tissue making machine in Algeria.

We will discuss the challenges faced by clients in Algeria, the solutions offered by our company and the positive impact it has had on their businesses.

Customer profile:

Our client, a leading manufacturer of hygiene products in Algeria, wanted to expand its product line with the launch of disposable compressed facial wipes. They were looking for a reliable, efficient machine that could produce high-quality towels at a faster rate to meet the growing market demand. Challenges: Customers face several challenges in manufacturing disposable compressed face towels.

Some major obstacles include:

1. Limited production capacity: Existing production processes are manual and time-consuming, limiting their ability to meet growing demand.

2. Unstable quality: Manual processing results in inconsistent towel sizes and quality control issues, hindering customer satisfaction.

3. Labor-intensive operations: High labor costs and reliance on manual labor affect overall efficiency and profitability.

solution:

Our company is a well-known manufacturer of hygiene products machinery and equipment, providing tailor-made solutions to customer challenges. We propose the installation of a scalable disposable fully automatic compressed facial tissue making machine, an automated system that can significantly increase production efficiency, enhance quality control, and reduce labor requirements.

Main features of the machine:

1. Automated production: Machines simplify the entire production process without manual intervention. It includes towel cutting, folding, compression, packaging and other functions.

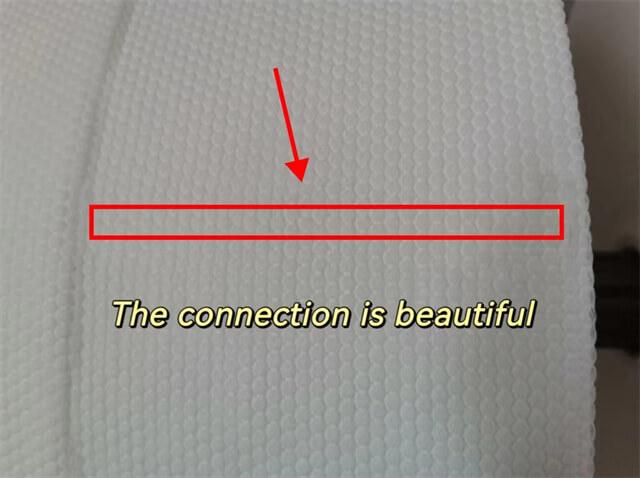

2. Customizable settings: The machine can adjust the towel size to ensure consistent quality and meet customers' specific requirements.

3. Increased productivity: With its high-speed production capabilities, machine productivity increases by up to 800% compared to manual processes.

4. Cost savings: Reduce labor dependence, improve energy efficiency and minimize material waste, saving customers a lot of costs.

Results and Impact:

The implementation of an expandable disposable compressed facial tissue making machine has had a positive impact on the business of our Algerian customers:

1. Increase production capacity: The machine enables them to meet growing market demand and expand their customer base.

2. Improved product quality: Consistent towel sizes and enhanced quality control improve customer satisfaction and brand reputation.

3. Cost-effectiveness: Lower labor costs and improved operational efficiency lead to higher profitability.

4. Competitive Advantage: The ability to offer disposable compressed facial wipes differentiates our customers from competitors and opens up new business opportunities.

Conclusion:

By installing a scalable disposable compressed facial tissue making machine, our Algerian customer was able to overcome production challenges and achieve significant business growth. The success of this implementation highlights the importance of adopting innovative and automated solutions in manufacturing, ultimately improving efficiency, quality and profitability.

Nonwoven Machines Market Leader!