HB Is A Manufacturer Of Double Layer 3D Lamination Embossing Machine For Baby Diapers

![]() Price: Negotiable

Price: Negotiable

![]() Model: HBJX-FB650SS with double layer single release and double recovery

Model: HBJX-FB650SS with double layer single release and double recovery

![]() Power: three-phase; 380V;50Hz. Installed power: ≤ 40KW

Power: three-phase; 380V;50Hz. Installed power: ≤ 40KW

![]() Dimensions: (L*W*H):6.0*2.0*2.5M(for reference)

Dimensions: (L*W*H):6.0*2.0*2.5M(for reference)

![]() Raw Material Specifications: Minimum cutting width: 65mm;Maximum rolling width: 650mm

Raw Material Specifications: Minimum cutting width: 65mm;Maximum rolling width: 650mm

![]() Equipment Color: Rack metal silver aluminum alloy+gray white sheet metal outer frame

Equipment Color: Rack metal silver aluminum alloy+gray white sheet metal outer frame

![]() Raw Material: Hot air surface layer non-woven fabric 35-45g/M ²

Raw Material: Hot air surface layer non-woven fabric 35-45g/M ²

![]() Speed: Design speed: 90M/Min. Actual production speed: 45-75M/Min

Speed: Design speed: 90M/Min. Actual production speed: 45-75M/Min

![]() Qualified Rate: ≧97%

Qualified Rate: ≧97%

![]() Configuration: Full servo power double-layer compound embossing machine

Configuration: Full servo power double-layer compound embossing machine

![]() Certification: CE, ISO

Certification: CE, ISO

![]() Working Voltage: 380V

Working Voltage: 380V

![]() Working Air Pressure: 6Bar

Working Air Pressure: 6Bar

![]() Temperature Range: 0℃-45℃

Temperature Range: 0℃-45℃

![]() Place of Origin: CHINA.

Place of Origin: CHINA.

The non-woven double layer 3D lamination embossing machine is an advanced and efficient device designed for enhancing the quality and appearance of non-woven materials. With its innovative design and cutting-edge technology, this machine offers exceptional performance and versatility in various industries.

Main technical parameters

|

Equipment name/model |

Double layer 3D composite embossing machine (HBJX-FB650SS with double layer single release and double recovery) |

|

Production product |

Hot air surface layer non-woven fabric 35-45g/M ² |

|

Power Supply |

three-phase; 380V;50Hz.Installed power: ≤ 40KW (including mold heating) |

|

Design and production speed |

Design speed: 90M/Min. Actual production speed: 45-75M/Min (according to mold pattern) |

|

Production material specifications |

Maximum winding width ≤ 650mm; Maximum winding diameter: ф 1000mm; Minimum cutting width: 65mm. Maximum unwinding weight: 150KG |

|

Overall dimensions (m) |

(L*W*H):6.0*2.0*2.5M(for reference) |

|

Equipment color |

Rack metal silver aluminum alloy+gray white sheet metal outer frame |

|

Qualification rate |

Qualification rate ≥ 97% (excluding material replacement joints and edge cutting materials) |

|

Preparation scheme |

Preparation of full servo power double-layer compound embossing machine |

Technical Features:

1. Double Layer Lamination: This machine utilizes a double-layer lamination process, ensuring a strong and durable bond between non-woven layers.

2. 3D Embossing: Equipped with state-of-the-art embossing technology, it creates exquisite and intricate 3D patterns on non-woven materials, adding a touch of elegance and uniqueness.

3. High Efficiency: The machine is engineered to deliver high production output, allowing for increased productivity and reduced time and labor costs.

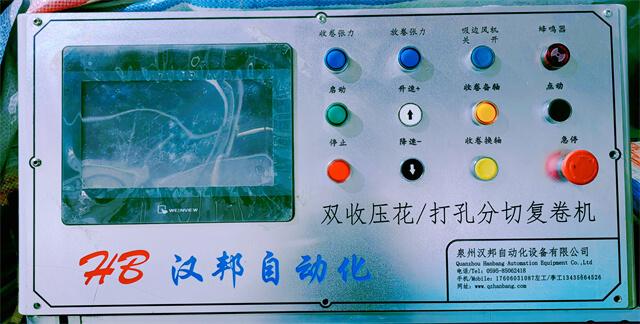

4. Precise Control System: It features a precise control system that enables accurate adjustment of parameters such as pressure, temperature, and speed, ensuring consistent and reliable results.

5. User-Friendly Interface: The intuitive interface makes it easy for operators to monitor and control the machine, minimizing the learning curve and maximizing efficiency.

Precautions:

1. Ensure proper alignment of materials before lamination to avoid misalignment during the process.

2. Regularly clean and maintain the machine to ensure optimal performance and longevity.

3. Follow all safety guidelines and precautions when operating the machine to prevent accidents or injuries.

4. Train operators thoroughly on machine operation and maintenance to maximize efficiency and minimize errors.

5. Use only recommended non-woven materials suitable for lamination and embossing in this machine to achieve desired results.

1. Lamination: The machine effectively laminates two layers of non-woven materials, providing enhanced strength and stability.

2. Embossing: It creates intricate 3D patterns on non-woven materials, adding texture and visual appeal.

3. Temperature Control: The machine offers precise temperature control to ensure proper lamination and embossing without damaging the material.

4. Pressure Adjustment: Operators can adjust the pressure according to the specific requirements of the materials being processed.

5. Speed Control: The speed of the machine can be adjusted to achieve optimal production efficiency and quality.

Double Layer 3D Lamination Embossing Machine Applications:

This lamination embossing machine finds extensive applications in various industries, including:

1. Packaging Industry: It is ideal for enhancing the visual appeal of non-woven bags, gift wraps, and other packaging materials, making them more attractive and eye-catching.

2. Textile Industry: The machine can be used for lamination and embossing of non-woven fabrics used in automotive interiors, upholstery, and home furnishing items, enhancing their appearance and durability.

3. Medical Industry: It is suitable for manufacturing high-quality medical gowns, masks, and other non-woven medical products, ensuring superior strength and aesthetics.

We've seen a noticeable increase in efficiency since integrating the Double Layer 3D Lamination Embossing Machine into our operations.this machine has significantly reduced our production costs while maintaining the highest standards of output quality.Nicholas 2024-06-01

The Double Layer 3D Lamination Embossing Machine has been a catalyst for the growth of our business, enabling us to take on more ambitious projects."Jafferson Clinton 2024-06-20