introduce:

We will explore the success story of a Lithuanian customer who invested in a portable mini compressed facial tissue making machine.

Customer Mr. Jonas recognized the growing demand for portable sanitary towels in Lithuania's beauty and tourism industries. To tap into this market, Mr. Jonas decided to invest in a state-of-the-art manufacturing machine to produce compressed facial tissues.

Market analysis:

Lithuania's beauty and tourism industry has experienced significant growth in recent years. Consumers are increasingly looking for convenient, portable products to enhance their skin care routines on the go. Recognizing this trend, Mr. Jonas conducted thorough market research to gain a deep understanding of customer preferences and needs. The study revealed a gap in the market for portable, eco-friendly and hygienic face wipes.

Investment decision:

After carefully considering the options, Mr. Jonas decided to invest in a portable mini compressed facial tissue making machine from renowned international supplier HANGBANG. The decision was driven by several factors, including the machine's compact size, ease of use and ability to consistently produce high-quality compressed facial wipes.

Machine features:

The portable mini compressed facial tissue making machine attracted Mr. Jonas with its advanced technology and features.

Some noteworthy features include:

1. Fully automated operation: The machine can automatically process raw materials, compress them into small towels, and package them, with almost no manual intervention required.

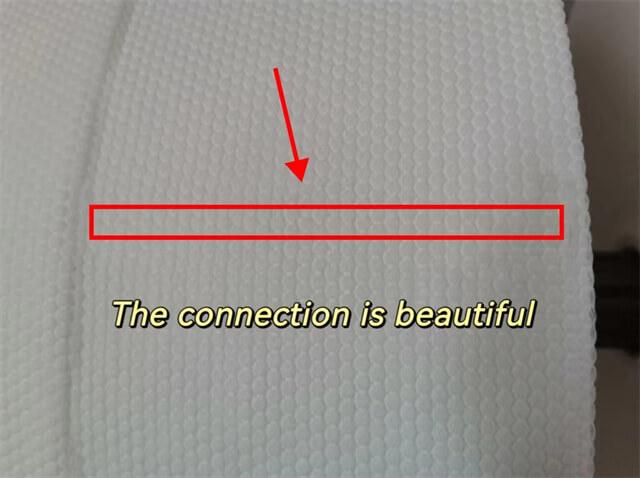

2. Quality control mechanism: This machine adopts a quality control system to ensure that each towel meets the highest hygiene and durability standards.

3. Versatility: The machine is capable of producing towels of different sizes and can be customized according to the customer's specific requirements. Production Process: After receiving the machine, Mr. Jonas set up a small production facility in Lithuania.

The production process includes the following steps:

1. Raw material selection: Mr. Jonas purchases fully viscose spunlace non-woven environmentally friendly materials, which are gentle to the skin and easy to decompose.

2. Compression cutting: The machine compresses the raw materials into small, easy-to-carry towels and automatically cuts them into the required size.

3. Packaging: Pack the compressed towels individually in hygienic and environmentally friendly packaging.

Marketing and Distribution:

To promote his products, Mr. Jonas implemented a comprehensive marketing strategy that included online advertising, participation in trade shows, and partnerships with local beauty salons and travel agencies.

In addition, he has established partnerships with distributors and retailers to ensure that his compressed face towels are widely sold throughout Lithuania.

Results and success:

Thanks to Mr. Jonas’ strategic investment and effective marketing efforts, the Portable Mini Compressed Face Towel has gained huge popularity in Lithuania. Consumers appreciate the convenience, portability and environmental friendliness of towels. Sales have grown steadily, production capacity has been expanded, and market penetration has been further deepened.

Conclusion:

Mr. Jonas’s success story highlights the importance of identifying market trends and investing in innovative manufacturing solutions. With the help of the portable mini compressed facial tissue making machine, Mr. Jonas is able to meet the growing demand for portable sanitary towels and position his brand as a leader in the Lithuanian beauty and tourism industry.

Nonwoven Machines Market Leader!