This case demonstrates the successful business cooperation between Hanbang Company, a well-known non-woven fabric embossing and Perforating slitting machine For Paper Diaper manufacturer, and a Bangladeshi customer.

By understanding customer needs and providing efficient solutions, both parties have achieved impressive results in the growing compressed towel industry.

Customer background:

The customer, a leading Bangladeshi company specializing in the production of air-through nonwoven materials, recognized the need for a high-quality and efficient nonwoven embossing machine to enhance their manufacturing capabilities.

Their goal is to increase production efficiency, improve product quality and meet the growing needs of local and international customers.

Manufacturer background:

The manufacturer is a global leader in nonwoven processing machinery For Diaper and has been providing cutting-edge solutions to customers around the world.

Their expertise lies in designing and manufacturing advanced embossing machines to meet the needs of various industries including the hygiene industry, cleaning industry.

Cooperation Process:

1. Initial consultation:

The manufacturer conducts an initial consultation with the customer to gather information about their specific requirements, including required embossing patterns, production volumes and budget constraints.

They also gain a deep understanding of the client's operational processes, growth plans and target markets.

2. Customized solutions:

Based on the information gathered, the manufacturer proposes a customized nonwoven embossing machine to meet the customer's unique needs. The solution features adjustable embossing patterns, high production speeds and easy operation.

3. Trial phase:

To ensure the effectiveness of the proposed solution, the manufacturer arranged a trial period during which customers could test the machines in their production facilities.

This allows customers to experience the machine's performance, make necessary adjustments, and provide feedback for further improvements.

4. Installation and training:

Once the customer approved the machine's performance, the manufacturer sent a technical team to Bangladesh for installation and training.

This comprehensive training ensures that customers' operators are proficient in operating, maintaining and troubleshooting machines.

Results and benefits:

1. Improve production efficiency:

Nonwoven embossing machines For Baby Diaper enable customers to significantly increase their production capabilities.

With faster processing times and improved automation, productivity increases, allowing the company to meet growing demands and deadlines.

2. Improve product quality:

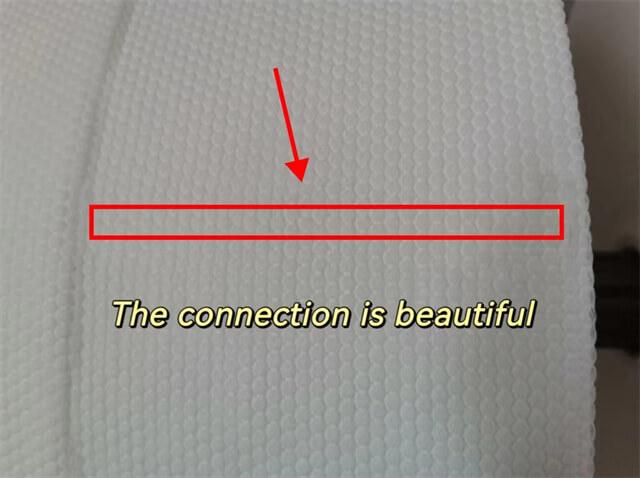

The precision technology of the embossing machine ensures consistent and high-quality embossed patterns on nonwoven fabrics.

This improves product aesthetics and customer satisfaction, thereby increasing sales and brand reputation.

3. Cost optimization:

Optimized machine design and advanced technology reduce energy consumption and minimize material waste, resulting in cost savings for customers.

Efficient production processes also reduce labor costs and improve overall operational efficiency.

in conclusion:

The successful cooperation between a nonwoven embossing machine manufacturer and a customer in Bangladesh demonstrates the importance of understanding customer needs and providing customized solutions.

By using advanced embossing machines, customers improve production efficiency, improve product quality and optimize costs.

This case is an example of how effective partnerships can drive success in the compressed towel industry.

Nonwoven Machines Market Leader!