The compressed towel industry in Bangladesh has experienced substantial growth in recent years due to the growing demand for convenient, eco-friendly personal hygiene products.

To meet this demand, manufacturers are increasingly integrating advanced machinery into their production processes.

This case focuses on a Bangladeshi customer who invested in a fully automatic compressed towel machine to improve production efficiency and quality.

Customer background:

Client ABC Textiles Ltd. is a leading manufacturer and exporter of compressed towels in Bangladesh.

With a reputation for superior product quality and prompt delivery, they have signed contracts with major domestic and international retailers.

However, as their business expands, they face challenges in maintaining productivity while meeting growing demand.

Challenges faced:

One of the major bottlenecks for ABC Textiles is the time-consuming and laborious process of manually folding and cutting spunlace nonwovens.

Traditional methods result in uneven fabric edges, inconsistent sizes and slower production speeds.

There was a clear need for a solution that ensures consistent product quality, reduces material waste and increases overall productivity.

solution:

After extensive research and consultation with industry experts, ABC Textiles decided to invest in a fully automatic towel compression machine.

The machine uses advanced technology to automate the entire process of folding, cutting, compression and molding of non-woven fabrics, ensuring precise positioning and eliminating human errors.

The machine's high-speed operation can significantly increase production capacity without affecting quality.

Benefits and results:

After installing a fully automatic compressed towel machine, ABC Textiles experienced some significant benefits, including:

1. Improve product quality:

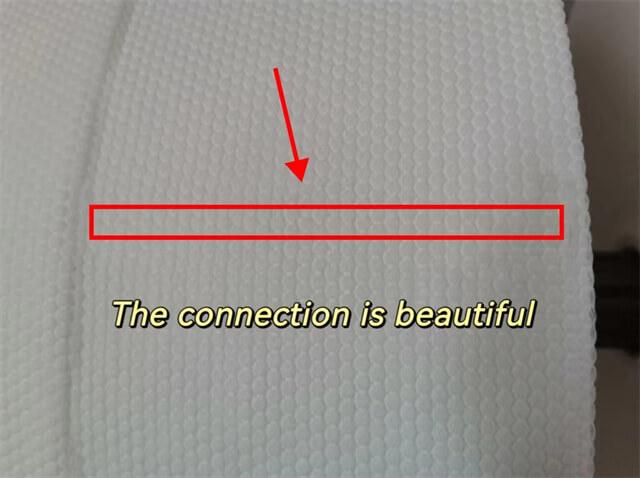

The machine's precise folding and cutting mechanism ensures consistent hole size and location, improving product quality and aesthetics.

2. Improve production efficiency:

By eliminating manual labor, the machine significantly reduces production time, allowing ABC Textiles to meet growing demand and improve overall efficiency.

3. Reduce material waste:

The automated process minimizes material waste due to inconsistent hole positioning, improving cost-effectiveness and sustainability.

4. Competitive advantage:

With increased production capacity and consistent product quality, ABC Textiles has gained a competitive advantage in the compressed towel market, attracting more customers and expanding its customer base.

in conclusion:

The deployment of a fully automatic compressed towel machine has enabled ABC Textiles to overcome production challenges and strengthen its position in the compressed towel industry.

By investing in advanced technology, the company has successfully improved product quality, increased efficiency, and gained a competitive advantage.

This case demonstrates the value of adopting innovative solutions to solve industry-specific challenges and achieve business growth.

Nonwoven Machines Market Leader!