In recent years, the compressed towel industry has witnessed significant growth globally.

One company that has successfully tapped into this market is ABC Towels Pvt. Ltd., a leading Bangladesh-based manufacturer of compressed towels.

This case explores how the implementation of a compressed towel machine helped ABC Towels streamline their production process, increase efficiency, and achieve remarkable success in the competitive market.

ABC Towels Pvt. Ltd. was established in 2010 with the aim of becoming a trusted provider of high-quality towels in Bangladesh. However, as the market evolved, the company realized the need to diversify its product offerings.

In 2019, they identified the potential of compressed towels, which are highly portable, space-saving, and eco-friendly.

To excel in this niche, ABC Towels knew they had to invest in advanced machinery capable of producing compressed towels efficiently.

The Solution:

After extensive research and evaluation, ABC Towels decided to invest in a state-of-the-art compressed towel machine.

They partnered with XYZ Machinery, a renowned manufacturer of such equipment, known for their cutting-edge technology and expertise in the industry.

The machine incorporated advanced features like automatic folding, packing, and sealing, ensuring rapid and precise production.

The installation of the compressed towel machine brought about several positive changes for ABC Towels.

Firstly, the production process became significantly faster, enabling them to meet increasing client demands without compromising on quality.

This resulted in reduced lead times and enhanced customer satisfaction.

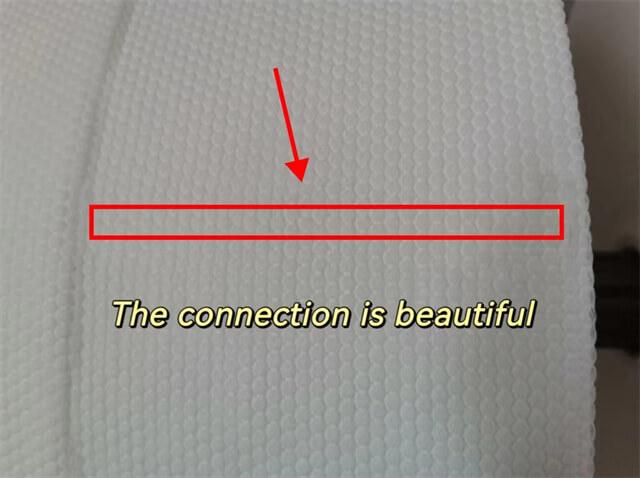

Moreover, the machine's automated features eliminated manual errors, resulting in a higher standard of consistency in each compressed towel produced.

One key advantage of the compressed towel machine was its ability to compress towels into various shapes and sizes, allowing ABC Towels to cater to the diverse needs of their clients.

Whether it was compact round towels for gyms or rectangular towels for hotels, the machine ensured flexibility in production.

Additionally, the machine's advanced packaging and sealing technology extended the shelf life of the compressed towels, making them more durable and hygienic. This opened up new opportunities for ABC Towels to expand their distribution network beyond Bangladesh, targeting international markets with confidence.

The successful implementation of a compressed towel machine revolutionized ABC Towels' production capabilities, enabling them to dominate the compressed towel industry in Bangladesh.

By investing in advanced machinery, they streamlined their production process, increased efficiency, and expanded their market presence.

This case study serves as a prime example of how embracing innovation can lead to growth and success in competitive industries.

Nonwoven Machines Market Leader!