Korean Client Success in the Compressed Bath Towel Machine Industry Introduction:

In recent years, the compressed bath towel industry has witnessed significant growth and innovation.

One of the key players in this industry is a Korean client who successfully established their business through the implementation of advanced compressed bath towel machines.

This case study presents an overview of their journey and highlights the benefits they achieved from this technology.

Background:

The Korean client, a leading importer and distributor of various household products, recognized the growing demand for compact and eco-friendly bath towels. They aimed to capitalize on this trend by offering high-quality compressed bath towels to consumers.

However, traditional manufacturing methods were time-consuming and lacked efficiency.

To overcome these challenges, the client turned to compressed bath towel machines manufactured by an international supplier.

Implementation and Operational Efficiency:

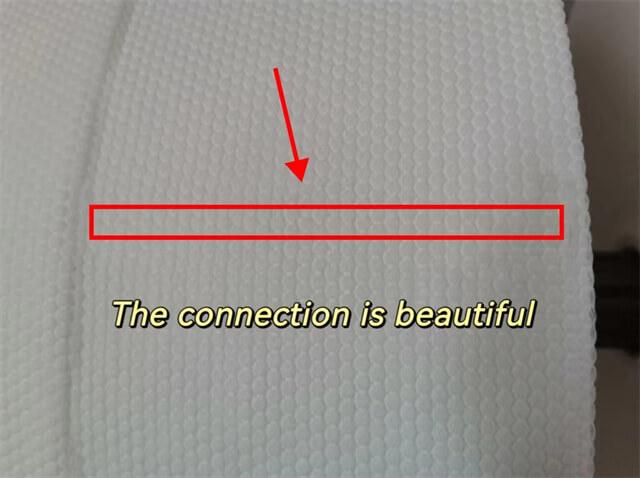

The Korean client invested in state-of-the-art compressed bath towel machines that offered automated processes, including cutting, folding, and compressing the towels.

These machines utilized advanced technology, such as computer-controlled systems and precision cutting mechanisms, to ensure consistency and accuracy in towel production.

The implementation of these machines significantly improved productivity and operational efficiency for the client.

Product Innovation and Customization:

The compressed bath towel machines enabled the Korean client to explore product innovation and customization.

With the ability to control towel thickness, fabric material, and design patterns, they could cater to the diverse preferences of their target customers.

The machines allowed for quick and seamless customization, giving the client a competitive edge in the market.

Sustainability and Cost Reduction:

The compressed bath towel machines facilitated the Korean client's commitment to sustainability.

By reducing their reliance on traditional manufacturing processes, which often result in excessive waste, the client could produce eco-friendly towels that were compressed into smaller sizes.

This not only saved storage space but also reduced shipping costs and carbon emissions.

Market Expansion and Profitability:

Equipped with the compressed bath towel machines, the Korean client efficiently met the rising demand for their products.

Their ability to offer a range of customized towels to various industries, including hotels, spas, and airlines, helped them expand their market presence and increase profitability.

The client's commitment to quality, coupled with the efficiency of the machines, garnered a positive reputation among customers and contributed to their business success.Conclusion:

This case study highlights how a Korean client in the compressed bath towel industry leveraged advanced technology to achieve significant benefits.

By implementing state-of-the-art compressed bath towel machines, the client improved operational efficiency, achieved product innovation and customization, promoted sustainability, expanded their market reach, and increased profitability.

This success story serves as an inspiration for businesses in the industry looking to enhance their competitiveness and meet the evolving demands of consumers.