Non woven embossing & perforating slitting machine(single unwinder and double rewinder)

![]() Price: Negotiable

Price: Negotiable

![]() Model: HBJX-W1600-SD

Model: HBJX-W1600-SD

![]() Power: Three-phase, 380V, 50HZ. Total installed power:35KW

Power: Three-phase, 380V, 50HZ. Total installed power:35KW

![]() Finished Product Specifications: Width 85-1600mm, roll diameter 850mm

Finished Product Specifications: Width 85-1600mm, roll diameter 850mm

![]() Raw Material: Air-through nonwovens and spunbond nonwovens

Raw Material: Air-through nonwovens and spunbond nonwovens

![]() Speed: Design speed: 95M/min. Actual production speed: 50-85M/min

Speed: Design speed: 95M/min. Actual production speed: 50-85M/min

![]() Dimensions: length * width * height = 6.0* 2.8* 2.5 meters (1600 model)

Dimensions: length * width * height = 6.0* 2.8* 2.5 meters (1600 model)

![]() Qualified Rate: ≥98%

Qualified Rate: ≥98%

![]() Configuration: With single unwinding and double rewinding, the machine does not stop or slow down, and the output is higher.

Configuration: With single unwinding and double rewinding, the machine does not stop or slow down, and the output is higher.

![]() Equipment Color: Host default gray white + stainless steel plate

Equipment Color: Host default gray white + stainless steel plate

![]() Certification: CE, ISO

Certification: CE, ISO

![]() Working Voltage: 380V

Working Voltage: 380V

![]() Working Air Pressure: 6Bar

Working Air Pressure: 6Bar

![]() Temperature Range: 0℃-45℃

Temperature Range: 0℃-45℃

![]() Place of Origin: CHINA.

Place of Origin: CHINA.

Welcome to the world of Non woven embossing & perforating slitting machine! This efficient non-woven embossed punching and slitting machine can not only greatly improve your production efficiency, it does not slow down or stop during the winding and unwinding process, and it automatically connects, so you don’t have to worry during the operation. Waste of time and energy.

The main technical parameters

|

Device name/model |

Single layer non-woven universal embossing/perforating composite machineHBJX-W1600-SD |

|

product |

Single layer hot air surface non-woven fabric 18-35g/m2 |

|

power supply |

Three-phase; 380V; 50Hz—Installed power: <=35KW (including mold heating) |

|

Design and production speed |

Design speed: 90M/min. Actual production speed: 50-85M/Min (according to mold pattern) |

|

Production material specifications |

Maximum rewinding and unwinding width <=1630mm; maximum unwinding diameter: ф1200mm; maximum rewinding diameter: ф850, minimum slitting width: 85mm. Maximum unwinding weight: 200KG Maximum rewinding weight: 85KG |

|

Overall dimensions (meters) |

(L*W*H):6.0*2.8*2.5M (for reference) |

|

Device color |

Rack metal silver aluminum alloy + gray and white sheet metal frame |

|

qualification rate |

Qualification rate ≧98 (excluding replacement joints and trimming materials) |

|

configuration plan |

Full servo power single layer composite embossing machine configuration |

The non-woven embossed perforating and slitting machine adopts the most advanced technology and the highest quality materials, making it reach the highest standards in performance and quality. It can easily handle non-woven fabrics of various materials and thicknesses, with clear embossing, accurate perforating, and neat cutting, making your products more beautiful and competitive.

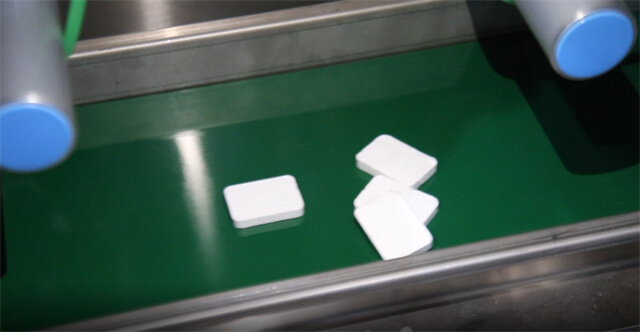

The production of hot-air non-woven fabrics or spun-bonded non-woven fabrics has a strong three-dimensional hole shape, is more beautiful, has higher quality, penetrates faster, does not reflect liquid, is soft and dry, has a more comfortable skin-friendly feel, and can more effectively overcome the impact of It has a stimulating effect on the skin and is more breathable and water-permeable. It is the first choice for the surface fabric of women's sanitary napkins, baby diapers and other products!

Main features: This machine is a multi-functional processing and production equipment. It can complete embossing, perforating, slitting and rewinding at one time.

1. Unwinding: The single-station non-woven fabric is equipped with photoelectric automatic correction, and the Xinjie servo motor automatically unwinds, driving the loading mechanism to connect the materials and using a seamless electric heating splicing device.

2. Embossed preheating group: It adopts oil temperature thermal cycle heating, and the hole shape shaping effect is good. Double copper laminated pattern, strong air cooling.

3. Slitting group: Using pneumatic pressure, the minimum cutting edge material can reach 3 mm, and there is no edge material device. The width error of the core roll and the outside is within 2mm. The end face is flat.

4. Rewinding: The central axis double-station is used to automatically switch the rewinding. The whole machine does not need to slow down or stop during the roll change operation, ensuring constant tension and improving the hole pattern perforating rate.

Control system: The whole machine is fully servo driven, using Xinjie PLC programming control and human-machine interface operation.

Main features: This machine is a multi-functional equipment that can complete punching, embossing, slitting and rewinding at one time. Production process: raw materials on the mach...

The production of hot-air non-woven fabrics or spun-bonded non-woven fabrics has a strong three-dimensional hole shape, is more beautiful, has higher quality, penetrates faster, do...

This machine is a multi-functional equipment for processing and production. It can complete drilling, slitting and rewinding at one time.Specification model: HBJX-W1600-DD type App...