Introduction:

The case revolves around a Saudi Arabia client who successfully implemented the High Speed Automatic Disposable Compressed Towel Machine in their business operations.

This machine is designed to automate the production of compressed towels, catering to the growing demand for disposable hygiene products in various industries.

Client Background:

The client operates in the hospitality industry and provides top-notch services to renowned hotels, resorts, and airlines in Saudi Arabia.

With a commitment to maintaining high hygiene standards, the client recognized the need for an efficient and automated solution for producing disposable compressed towels.

Challenge:

As the client's business expanded rapidly, they faced increasing pressure to meet the growing demand for compressed towels.

Manual production processes proved to be time-consuming, inefficient, and prone to errors. The client needed a reliable and high-speed solution that could significantly enhance productivity and maximize profitability.

Solution:

After careful research and considerations, the client decided to invest in the High Speed Automatic Disposable Compressed Towel Machine. This state-of-the-art machine offered numerous advantages, including:

1. High Production Speed: The machine operates at an impressive speed, producing a large number of compressed towels per minute. This allowed the client to meet the increasing demand from their customers promptly.

2. Automation and Efficiency: The machine eliminates the need for manual labor, reducing human error and improving overall efficiency. It streamlines the entire production process, from towel cutting to compression, packaging, and sealing.

3. Customizable Options: The machine offers customizable settings, allowing the client to produce compressed towels in different sizes, thicknesses, and packaging options. This flexibility enabled the client to cater to diverse customer requirements.

4. Hygienic and Eco-Friendly: The machine uses high-quality materials and follows strict hygiene standards, ensuring the production of clean and safe compressed towels.

Additionally, it optimizes material usage, reducing waste and promoting eco-friendly practices.

Results:

The implementation of the High Speed Automatic Disposable Compressed Towel Machine brought significant improvements to the client's operations:

1. Increased Production Capacity: With the machine's high-speed capabilities, the client experienced a substantial boost in production capacity. They were able to deliver more compressed towels to their customers within shorter lead times.

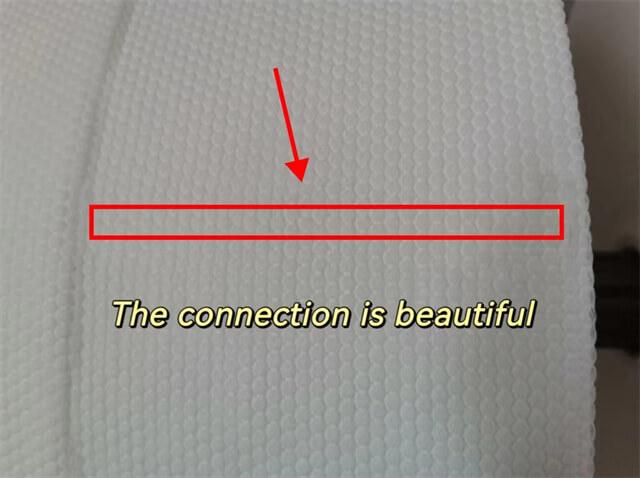

2. Enhanced Product Quality: The machine's automated processes minimized errors and inconsistencies, resulting in consistently high-quality compressed towels. This helped the client maintain their reputation for providing superior hygiene products.

3. Cost Savings: The automation of production processes reduced labor costs, as fewer workers were required to operate the machine. Additionally, optimized material usage led to cost savings in raw materials.

4. Customer Satisfaction: By meeting the growing demand efficiently, the client ensured customer satisfaction and strengthened their relationships with existing and new clients. This, in turn, increased their market competitiveness.

Conclusion:

The successful implementation of the High Speed Automatic Disposable Compressed Towel Machine proved to be a game-changer for the Saudi Arabia client. Through increased production capacity, improved product quality, and cost savings, the client was able to streamline their operations, meet market demands, and enhance customer satisfaction. The case demonstrates the tangible benefits of investing in advanced automation technology for businesses operating in the disposable hygiene product industry.

Nonwoven Machines Market Leader!