Compressed towel machines have revolutionized the hospitality industry, particularly in countries like Vietnam where tourism is booming.

This case presents a success story of a Vietnamese client who ventured into the compressed towel business and achieved remarkable results through the implementation of advanced machinery.

Background:

In recent years, Vietnam has witnessed a significant growth in tourism, leading to a surge in demand for convenient and portable personal care products such as compressed towels.

Recognizing this opportunity, Mr. Nguyen, an aspiring entrepreneur, decided to establish his own compressed towel production business.

Challenges:

When Mr. Nguyen initially entered the compressed towel industry, he encountered several challenges that hindered his progress.

These challenges included inefficient production processes, low production capacity, high labor costs, and inconsistent towel quality.

Realizing the need for modernization, he sought a solution through advanced compressed towel machines.

Solution:

After extensive research, Mr. Nguyen discovered an industry-leading manufacturer that specialized in high-quality compressed towel machines.

He invested in state-of-the-art machinery that automated the entire production process.

The machine could compress and package towels efficiently, significantly reducing labor requirements and ensuring consistent product quality.

Implementation:

Upon acquiring the compressed towel machine, Mr. Nguyen integrated it seamlessly into his production line.

The machine utilized advanced technology to compress towels quickly and effectively, while also offering customizable options for towel size, material, and packaging.

The automated process enabled higher production capacity, resulting in a significant increase in overall output.

Results:

The implementation of the compressed towel machine brought remarkable results for Mr. Nguyen's business:

1. Increased Production Capacity:

With the automated machine, Mr. Nguyen's production capacity increased by 300%, enabling him to meet the growing demands of his customers and expand his market reach.

2. Improved Efficiency:

The automated process reduced labor costs by eliminating the need for manual labor, allowing Mr. Nguyen to allocate resources to other business areas.

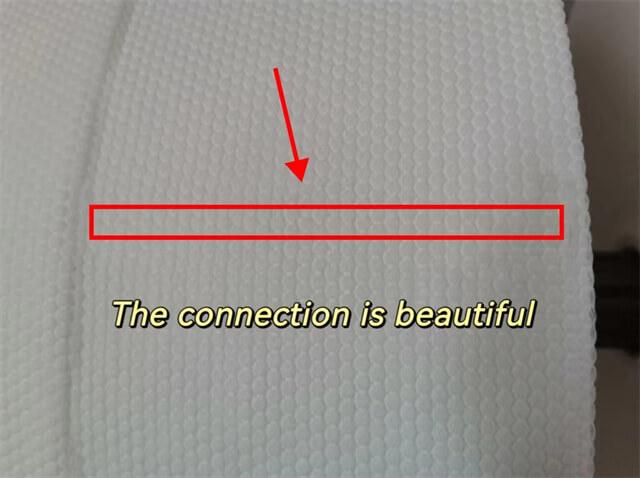

3. Consistent Product Quality:

The machine's precise compression and intricate folding techniques ensured consistent product quality, earning Mr. Nguyen a reputation for delivering superior compressed towels in the market.

4. Enhanced Profitability:

With higher production capacity, improved efficiency, and consistent product quality, Mr. Nguyen experienced a significant boost in profitability, enabling him to reinvest in his business and explore new opportunities within the industry.

Future Prospects:

With the success of his venture, Mr. Nguyen plans to expand his business further by establishing partnerships with hotels, airlines, and retail chains across Vietnam. He recognizes that the compressed towel industry still holds immense growth potential and aims to leverage his expertise and advanced machinery to dominate the market.

Conclusion:

This case study highlights the success story of a Vietnamese client in the compressed towel industry, showcasing how the implementation of advanced machinery transformed an aspiring entrepreneur into a thriving business owner.

Through the integration of a compressed towel machine, Mr. Nguyen overcame various challenges, achieving increased production capacity, improved efficiency, consistent product quality, and enhanced profitability.

His success serves as inspiration for other entrepreneurs looking to tap into the growing demand for compressed towels in Vietnam's flourishing tourism market.

Nonwoven Machines Market Leader!